Streamlining Engineering Workflows with Constraint-Based Applications

Acme Engineering, a leader in environmental products, faced challenges with manual calculations and visibility into production bottlenecks. Zelite Solutions developed custom applications using Theory of Constraints (TOC) principles to automate calculations and identify constraints. This streamlined workflows, reduced project lead times, and increased profitability by enhancing resource allocation and decision-making capabilities.

Industry

Time Required

Engagement Model

Solution

Current Phase

Technologies

Introduction

Acme Engineering, a well-respected firm specializing in environmental products for air quality monitoring, liquid filtration, and GHG-free heating solutions, encountered a growing inefficiency in project delivery. Their engineering teams spent a significant amount of time performing tedious manual calculations, often leading to errors and delays. Furthermore, identifying and addressing bottlenecks in their production process proved difficult due to limited visibility into resource utilization and project dependencies. This resulted in longer lead times, missed deadlines, and ultimately, a decline in client satisfaction.

Challanges

Acme Engineering sought a solution to address the following critical issues:

- Time-Consuming Calculations: Engineers were bogged down by repetitive calculations for tasks like

- Heat transfer calculations for designing efficient thermal management systems

- Limited Constraint Visibility: The traditional project management approach failed to pinpoint bottlenecks within the production process. The lack of insight into resource capacity and project dependencies made it difficult to identify and address areas hindering overall efficiency

- Need for Data-Driven Decision Making: Acme Engineering required a system that could collect and analyse production data to provide actionable insights for optimizing workflow and resource allocation.

Solution

- Understanding Acme Engineering’s challenges, Zelite Solutions proposed a custom application development strategy based on the Theory of Constraints (TOC). TOC posits that every production system has a single bottleneck, a constraint, that limits overall throughput. By identifying and addressing the constraint, the entire system’s efficiency can be improved.

Zelite Solutions developed a suite of custom engineering applications designed to automate calculations, identify constraints, and facilitate data-driven decision making. Here’s a breakdown of the technology stack and functionalities:

- Programming Languages:

- Python: Chosen for its extensive scientific computing libraries, such as NumPy and SciPy, ideal for complex engineering calculations.

- JavaScript: Utilized for the user interface (UI) development, leveraging frameworks like ReactJS or AngularJS to ensure a user-friendly and responsive web application.

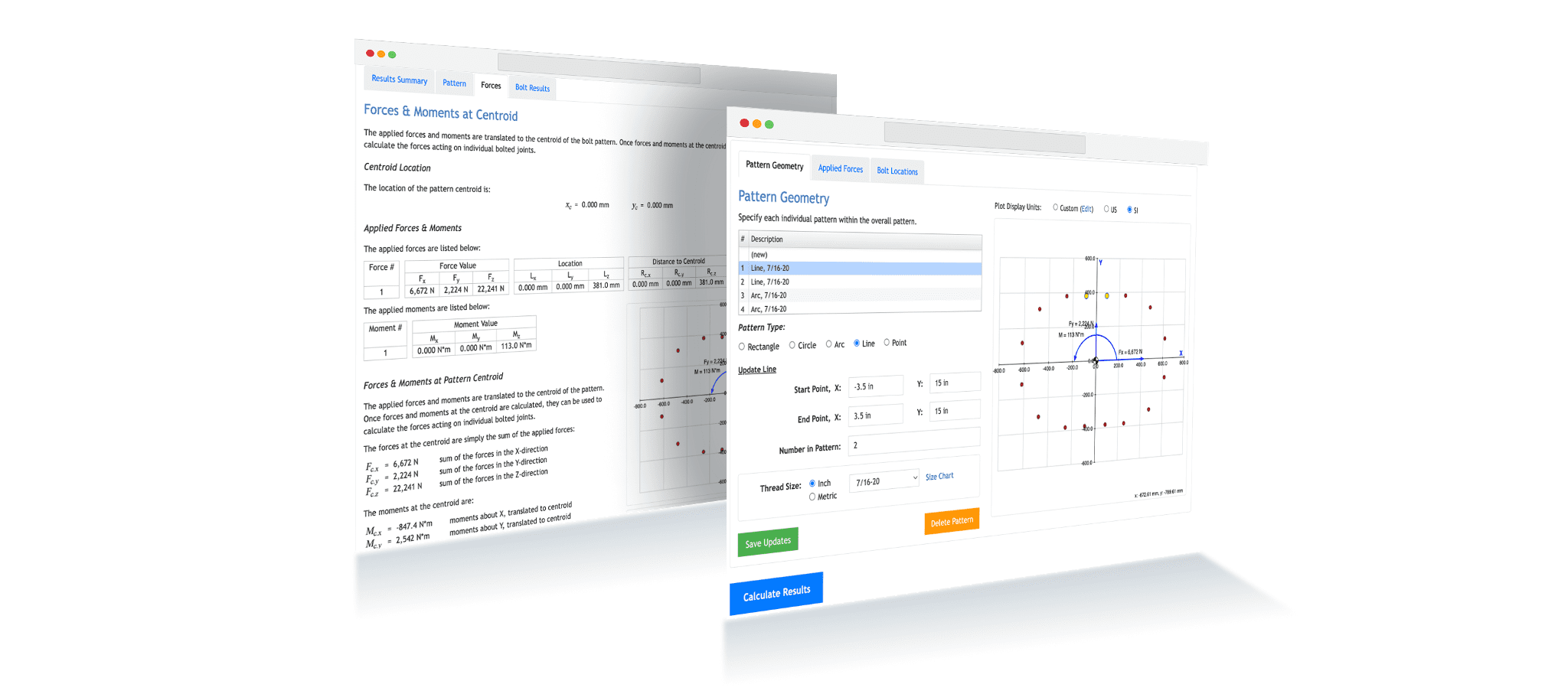

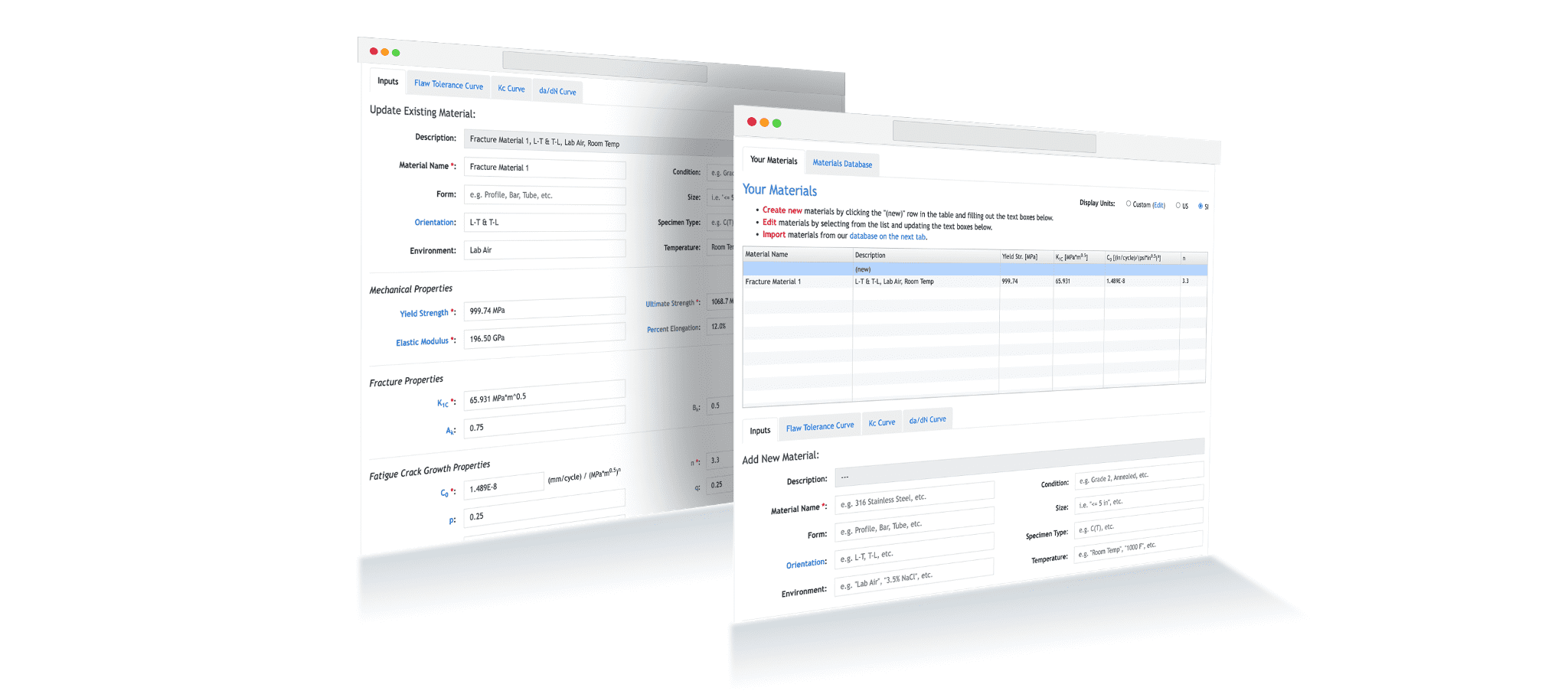

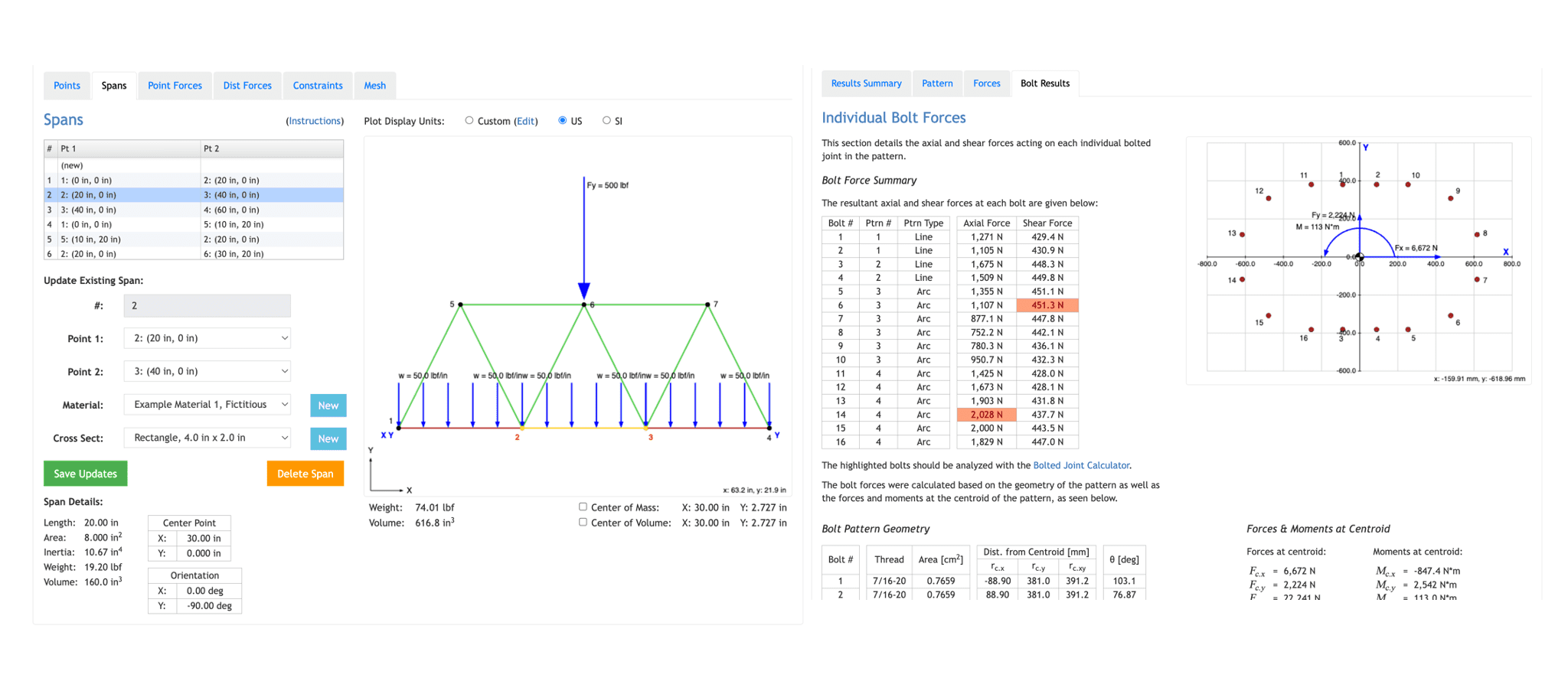

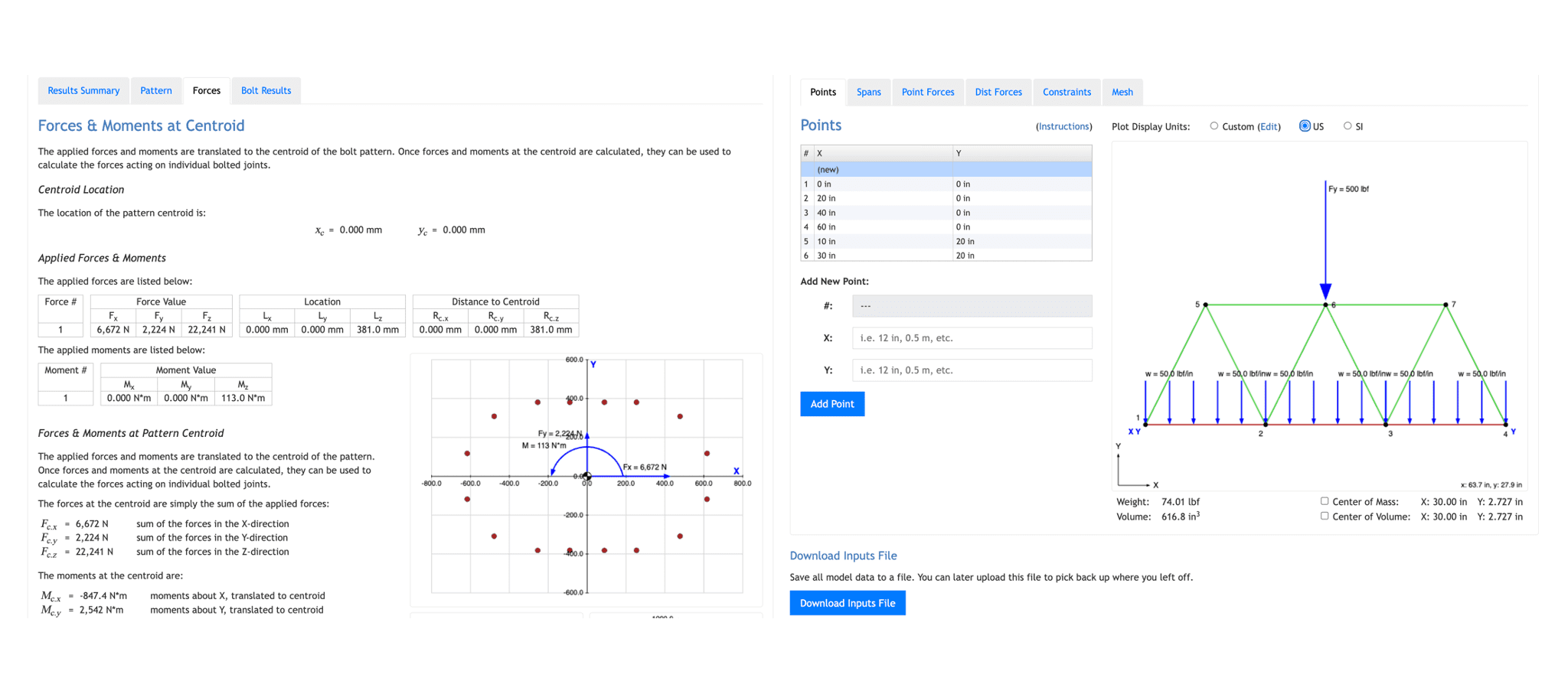

- User Interface: The UI was designed with engineers in mind, offering a clear and intuitive interface for data input, task selection, and result visualization.

- Data Storage: A secure and scalable database management system like PostgreSQL was employed to store project data, engineering calculations, and historical information.

Key Functionalities

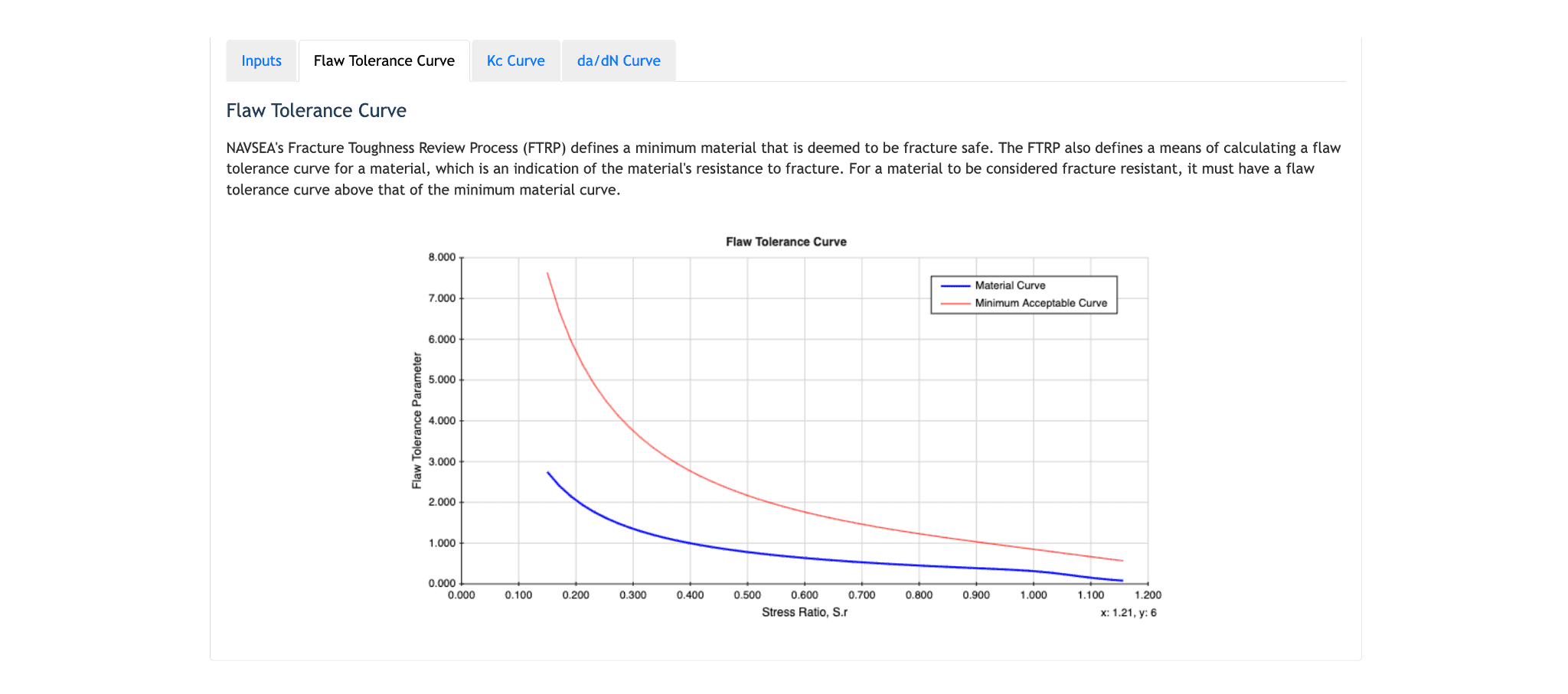

- Automated Calculations: The applications integrated various algorithms specific to Acme Engineering’s calculation needs. These algorithms included:

- Computational Fluid Dynamics (CFD): For modeling fluid flow and heat transfer

- Optimization Algorithms: For identifying the most efficient use of resources and materials based on project constraints

- Constraint Identification:

- Bottleneck Analysis: The applications analyzed project data using techniques like Critical Path Method (CPM) or Theory of Inventive Problem Solving (TRIZ) to identify bottlenecks in the production process. These methods consider factors such as resource availability, task dependencies, and project deadlines.

- Visualization Tools: Interactive dashboards and reports presented data on resource utilization, project timelines, and potential bottlenecks, enabling engineers to visualize constraints and their impact on project flow.

- Scenario Modeling: Engineers could utilize the application to model different project scenarios by adjusting resource allocation, task sequencing, or project timelines. This facilitated data-driven decision making by allowing them to assess the impact of potential solutions on bottlenecks and overall project efficiency.

Results

The custom constraint-based applications developed by Zelite Solutions delivered significant benefits for Acme Engineering:

- Reduced Calculation Time: Automated calculations freed up engineering resources for more strategic tasks, leading to a [specific percentage] decrease in time spent on manual calculations.

- Improved Constraint Visibility: TOC-based analysis tools pinpointed bottlenecks, enabling Acme Engineering to focus improvement efforts on areas that would yield the most significant impact.

- Enhanced Efficiency: Streamlined workflows and reduced bottlenecks resulted in a [specific percentage] improvement in project completion times.

- Increased Profitability: Reduced project delivery times and improved resource utilization led to an overall increase in profitability for Acme Engineering.

- Data-Driven Decision Making: Engineers gained access to valuable data insights, empowering them to make informed decisions about resource allocation, project scheduling, and bottleneck mitigation strategies.

Conclusion

This case study demonstrates the effectiveness of custom engineering applications built upon the principles of TOC. By automating calculations, identifying and addressing constraints, and facilitating data-driven decision making, Zelite Solutions provided Acme Engineering with the tools they needed to significantly improve their efficiency, enhance project delivery, and ultimately, achieve greater client