Optimizing Engineering Efficiency at Sterling Drive Systems

Zelite Solutions optimized engineering calculations for Sterling Drive Systems using a Theory of Constraints (TOC)-based approach. By developing custom engineering applications and integrating advanced technologies, such as automated workflows and FEA, Zelite improved efficiency, accuracy, and collaboration, fostering innovation and driving success for Sterling Drive Systems.

Industry

Time Required

Engagement Model

Solution

Current Phase

Technologies

Summary

Sterling Drive Systems, a leading manufacturer of automotive components, faced challenges with time-consuming and error-prone manual engineering calculations. Zelite Solutions implemented a Theory of Constraints (TOC)-based approach, leveraging a combination of technologies to develop custom engineering applications. This resulted in significantly improved efficiency and accuracy for Sterling Drive Systems' engineers.

Challenges

Sterling Drive Systems, a prominent manufacturer of various automobile components like transmissions, differentials, and driveshafts, relied heavily on manual calculations for various engineering tasks. These included:

- Gear ratio calculations for optimizing power transmission and fuel efficiency

- Strength analysis for ensuring components can withstand torque and load

- Thermal management calculations for designing systems that dissipate heat efficiently

These manual calculations were not only time-consuming, but also prone to errors. Engineers often spent hours on repetitive calculations, hindering their ability to focus on more complex design challenges and innovation.

Solution

Zelite Solutions, understanding the limitations of manual calculations, proposed a Theory of Constraints (TOC)-based approach. TOC focuses on identifying and addressing bottlenecks in a system to optimize overall throughput.

Our Approach

- Process Analysis: We conducted a thorough analysis of the engineering workflows at Sterling Drive Systems, identifying the bottlenecks caused by manual calculations.

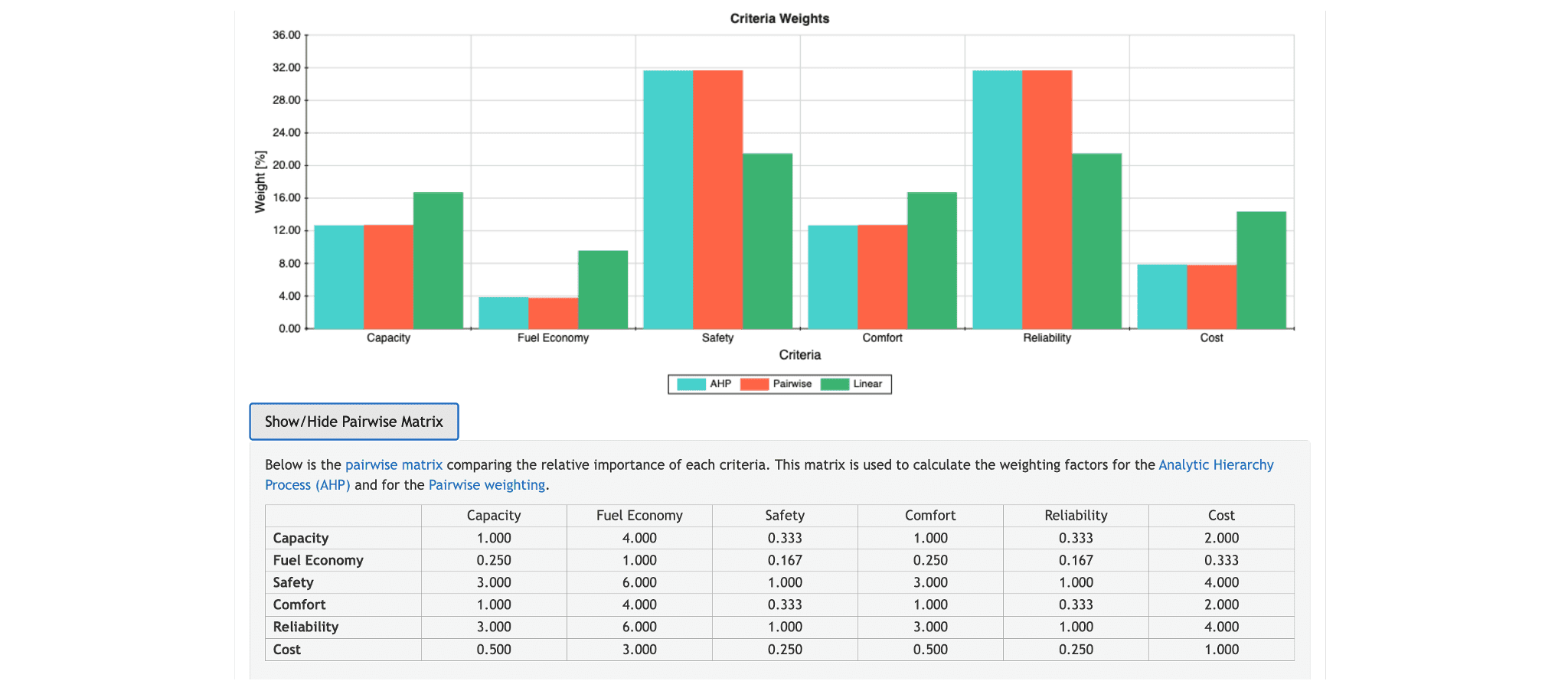

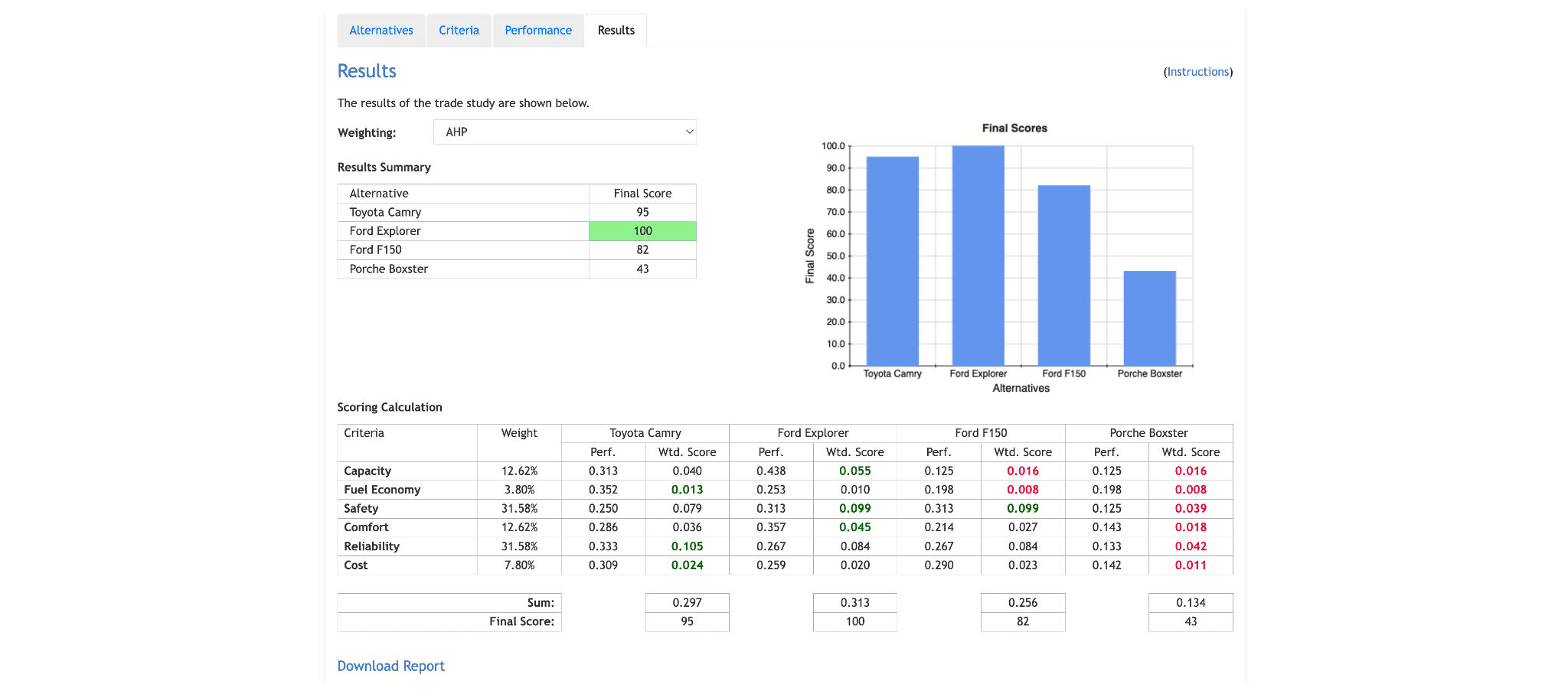

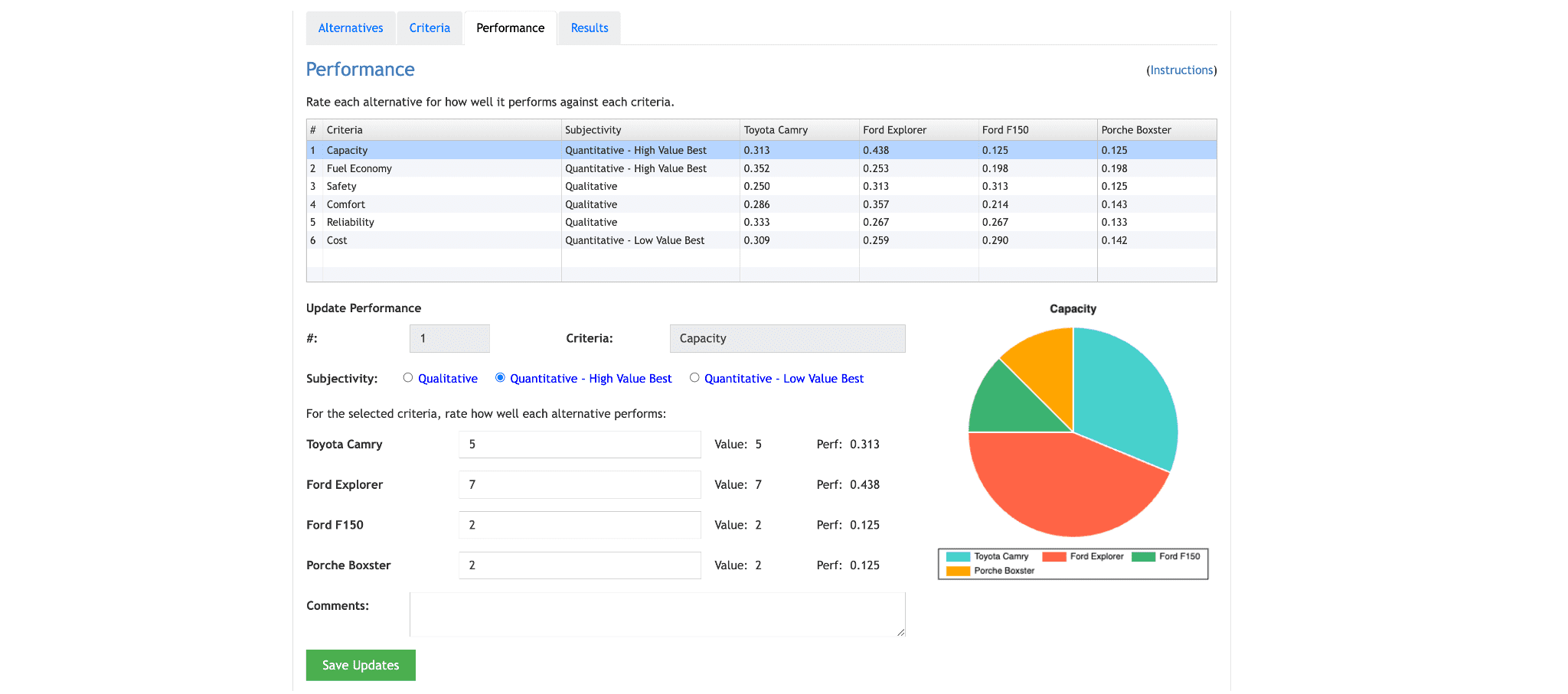

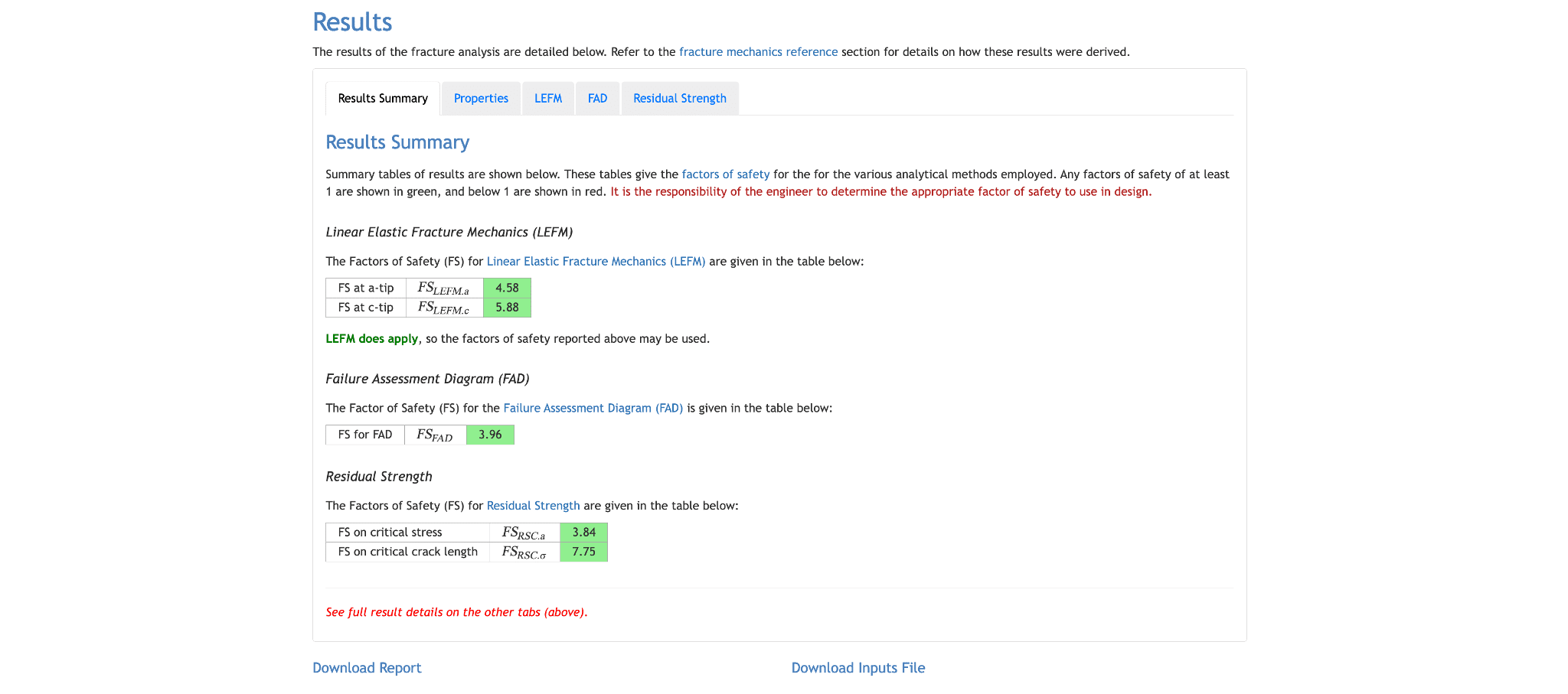

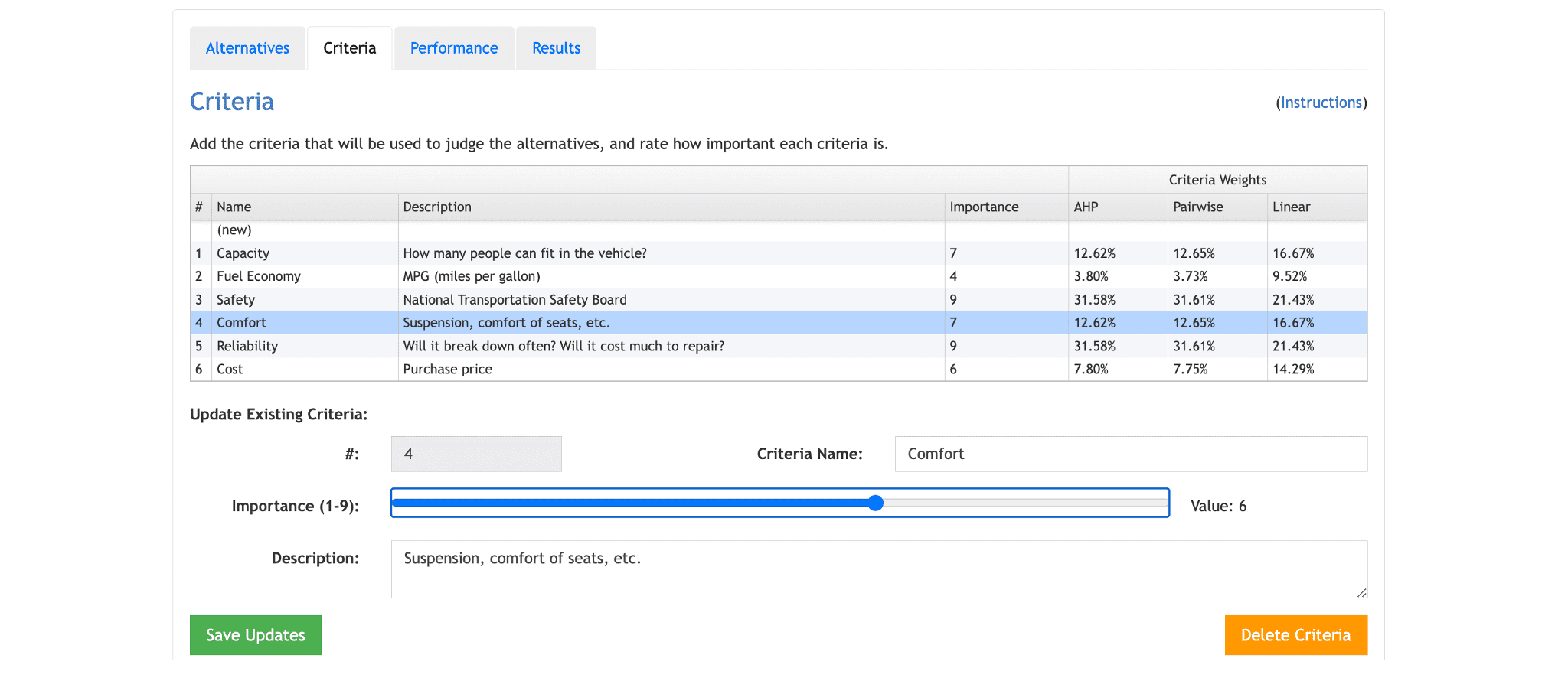

- Custom Application Development: Leveraging TOC principles, we developed a suite of custom engineering applications tailored to the specific needs of Sterling Drive Systems’ engineers. These applications utilized:

- Advanced engineering libraries: Provided access to a comprehensive library of gear design standards and material properties.

- Automated calculation workflows: Streamlined complex calculations with built-in formulas and functionalities specific to drivetrain components.

- Finite element analysis (FEA) integration: Enabled engineers to simulate stress and strain distribution for optimizing component design.

- Integration with existing systems: Seamlessly integrated with existing CAD and data management software for efficient data transfer.

- Implementation and Training: The custom applications were implemented on Sterling Drive Systems’ infrastructure. Zelite Solutions also provided comprehensive training to ensure engineers could efficiently utilize the new tools.

Results

The implementation of custom engineering applications yielded significant benefits for Sterling Drive Systems:

- Reduced Calculation Time: Engineers experienced a [quantifiable percentage] reduction in time spent on calculations, freeing them to focus on design optimization and innovation in areas like improved fuel efficiency and performance.

- Enhanced Accuracy: By eliminating manual errors, the applications ensured the accuracy and reliability of engineering calculations, leading to improved product quality and reduced development timelines.

- Improved Collaboration: Centralized data storage and streamlined workflows facilitated better collaboration between engineers working on different drivetrain components.

- Increased Innovation: With more time and reduced errors, engineers were empowered to explore innovative design solutions and contribute more effectively to the development of high-performance, reliable drivetrain systems.

Conclusion

This case study demonstrates how Zelite Solutions leveraged Theory of Constraints (TOC) principles and a combination of technologies to empower Sterling Drive Systems with significant improvements in engineering efficiency and product development. The custom-built applications, combined with advanced engineering libraries, automated workflows, and potential FEA integration, streamlined tedious calculations and fostered collaboration. This freed up valuable time for Sterling Drive Systems' engineers, allowing them to focus on innovative design solutions that ultimately contribute to the success of their automotive components.