Optimizing Production Flow with an Advanced Planning and Scheduling System

Zelite Solutions developed a custom Advanced Planning and Scheduling System (APS) for Amtek Auto Group, transforming their production flow with automated scheduling and real-time insights. The .Net-based system enhanced efficiency, reduced inventory costs, and improved customer satisfaction by optimizing resource utilization and ensuring timely deliveries.

Industry

Time Required

Engagement Model

Solution

Current Phase

Technologies

Introduction

In today’s demanding manufacturing environment, efficient production planning and scheduling are paramount for success. Amtek Auto, a prominent Indian manufacturer of forged automotive components, faced challenges in optimizing production due to:

- Manual Processes: Reliant on manual planning and scheduling, the system was time-consuming and prone to errors.

- Limited Visibility: Lack of real-time data and constraint consideration hindered optimal production planning decisions.

- Inventory Management Issues: Inefficient planning often led to excess or insufficient inventory levels, impacting both lead times and costs.

Challenges

Amtek Auto required an advanced planning and scheduling system to address these limitations and achieve:

- Improved Production Planning: Accurate and optimized production plans considering real-time constraints like machine capacity, material availability, and lead times.

- Enhanced Customer Satisfaction: On-time delivery through accurate scheduling fosters improved customer satisfaction.

- Reduced Inventory Levels: Optimized production plans minimize unnecessary inventory holding costs.

- Increased Productivity: Streamlined scheduling improves production efficiency and throughput.

The Solution

Zelite Solutions developed a comprehensive APS system built with .Net technology and a MySQL database. This scalable solution is designed for a phased global deployment, with the initial rollout at Amtek Auto’s Pune plant in India.

Key Features of the APS System:

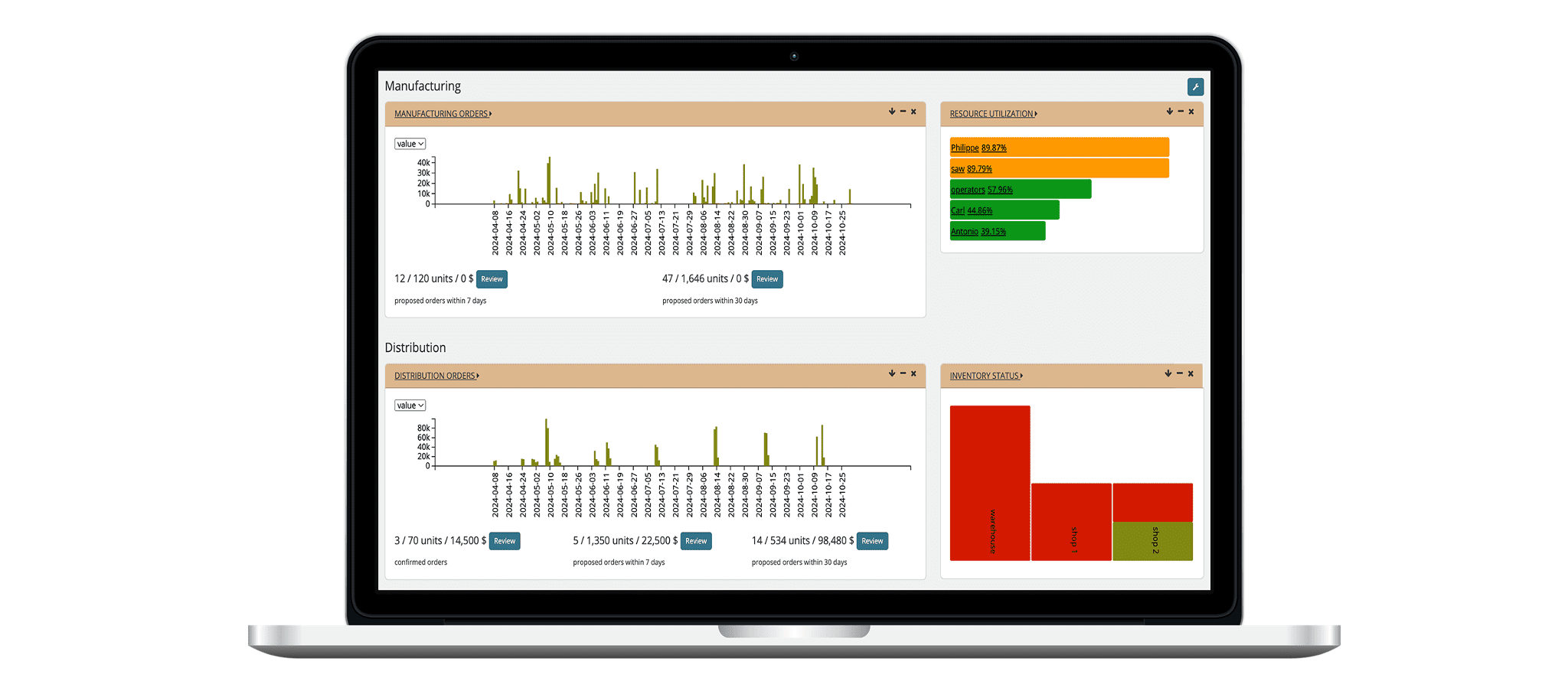

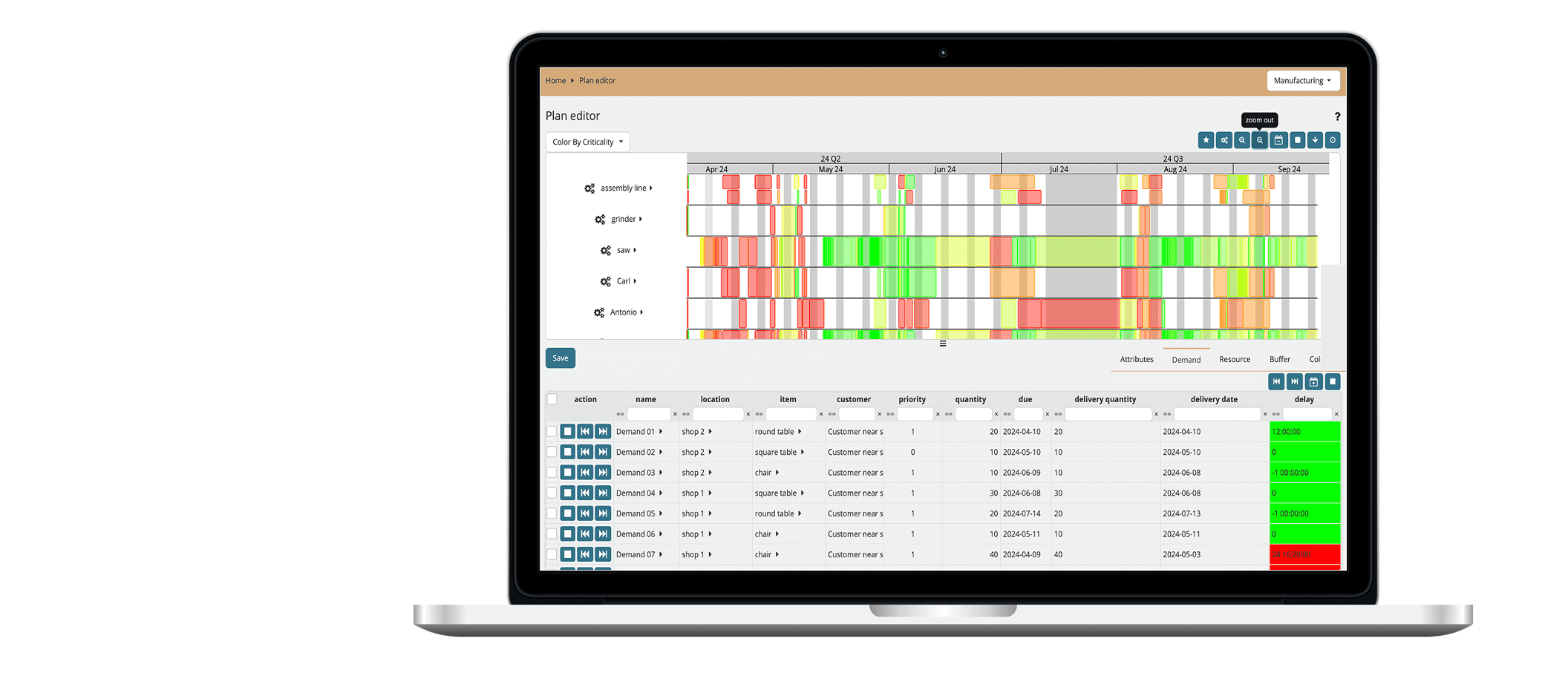

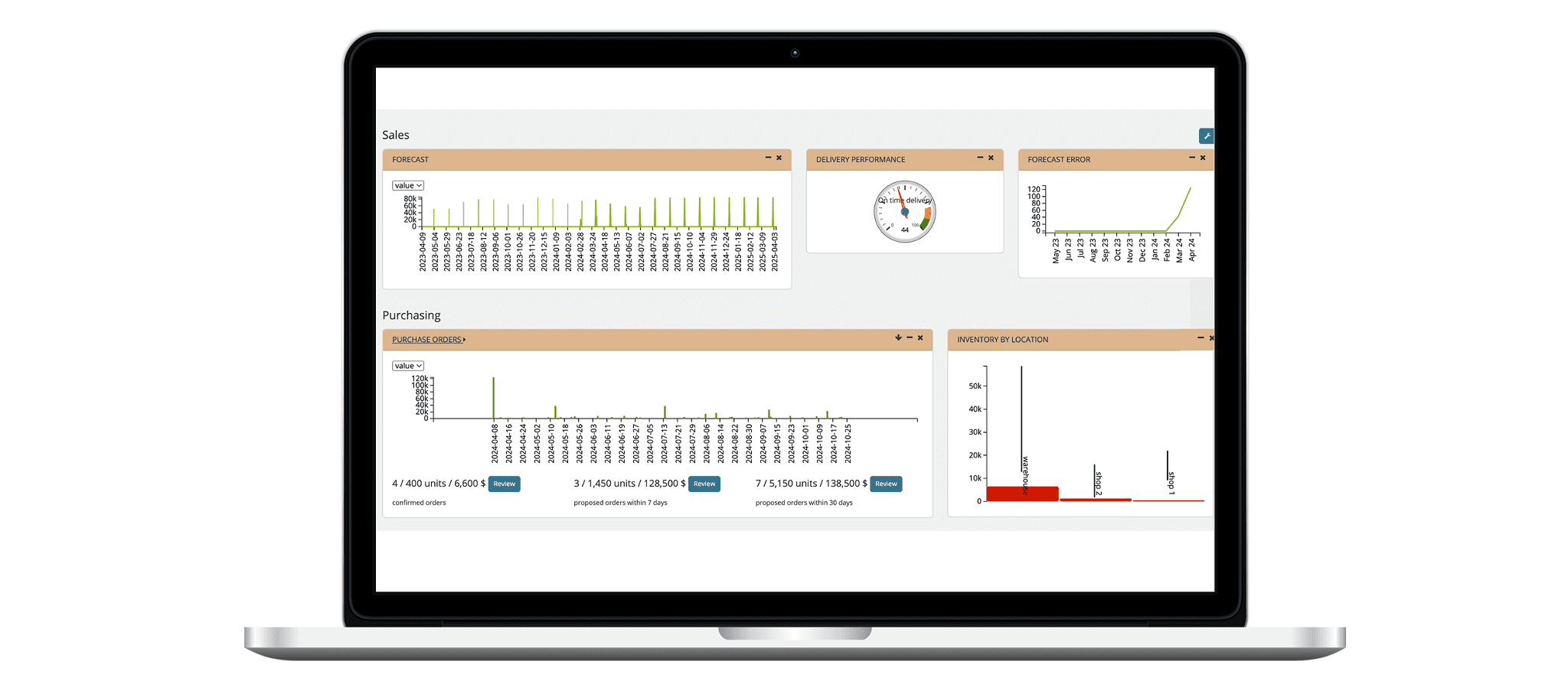

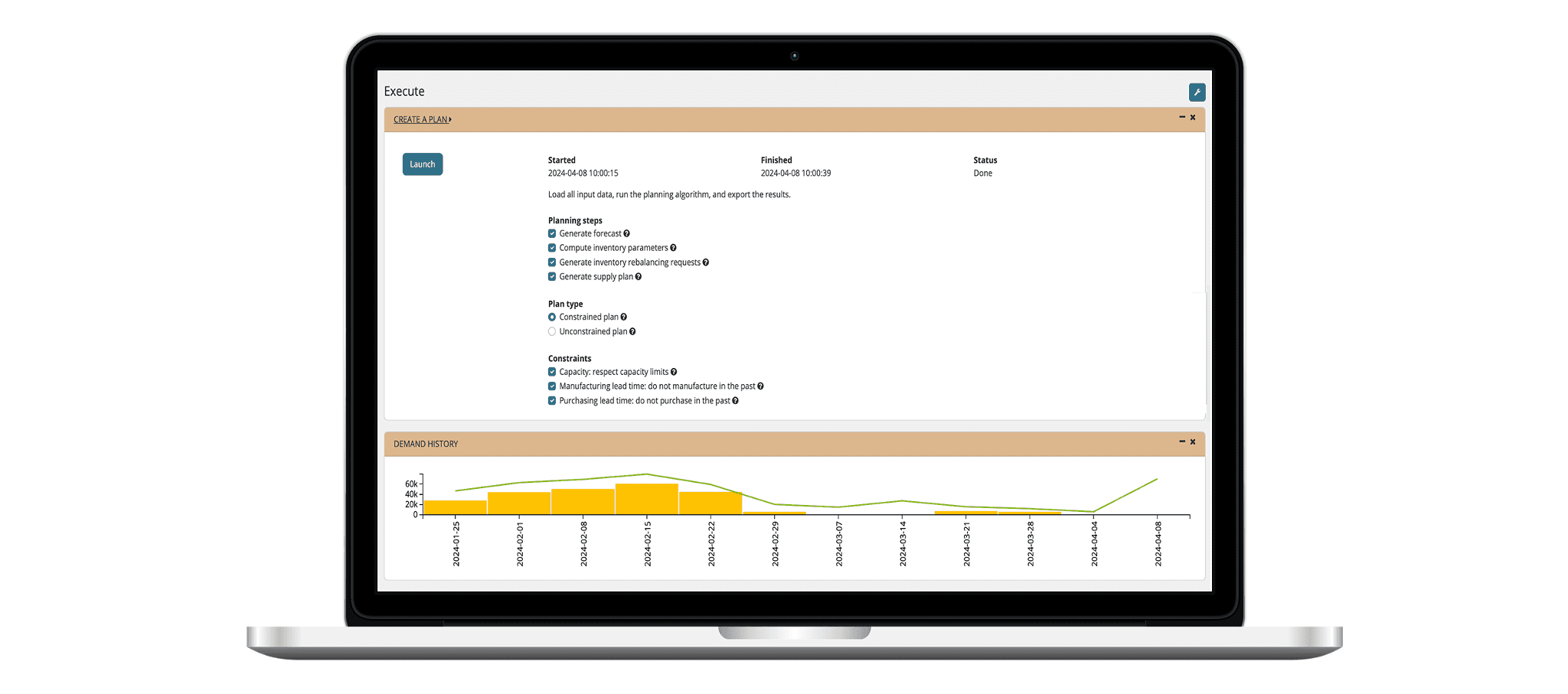

- Master Planning and Scheduling: Advanced functionalities for creating optimized production plans that consider real-time constraints, ensuring efficient production flow and on-time delivery.

- Constraint-Based Scheduling (CBS): The system incorporates Constraint-Based Programming (CBS) techniques to identify and address production bottlenecks proactively, leading to increased productivity.

- Capacity Planning: Enables Amtek Auto to effectively evaluate and optimize production capacity based on forecasted demand and resource availability.

- Route Exploding: Streamlines the process of breaking down complex production processes into individual steps and resource requirements, facilitating accurate planning.

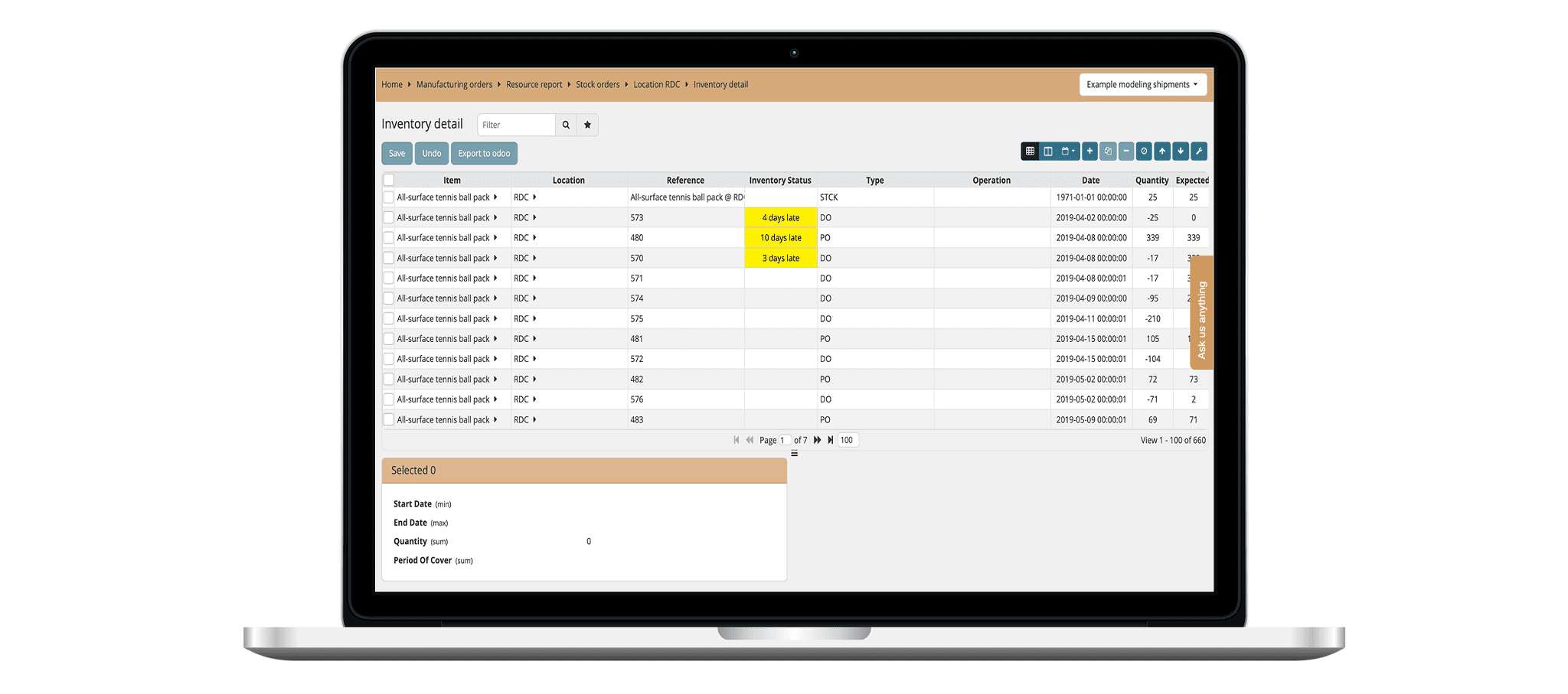

- Planning Capabilities: The system offers functionalities for demand forecasting, material requirements planning (MRP), and capacity planning, allowing for comprehensive production planning.

- Constraint Management and Analysis: Provides tools to identify, analyze, and address production constraints, ensuring smooth production flow and reduced lead times.

- Execution Control: Enables real-time monitoring and control of production processes, allowing for adjustments as needed based on actual conditions.

Deployment Strategy

The deployment strategy is phased for a global rollout:

- Phase 1: Initial deployment at the Pune plant in India, focusing on core functionalities like capacity planning, scheduling, and constraint management.

- Phase 2: Expansion to other Amtek Auto facilities across India, integrating with existing production management systems.

- Phase 3: Global deployment, catering to Amtek Auto’s international operations.

The Results

The custom APS solution empowered Amtek Auto to achieve significant improvements in their production planning and scheduling processes:

- Optimized Production Plans: Constraint-based scheduling ensures efficient production flow and on-time delivery, enhancing customer satisfaction.

- Reduced Inventory Levels: Optimized production plans minimize unnecessary inventory holding costs, leading to cost savings.

- Increased Productivity: Streamlined scheduling and constraint management result in increased production efficiency and throughput.

- Improved Decision Making: Real-time data and constraint visibility facilitate better production planning decisions.

Conclusion

This case study demonstrates the value of custom software solutions in optimizing production processes. Zelite Solutions' custom APS empowers Amtek Auto to gain a competitive edge through improved planning, scheduling, and resource allocation, ultimately leading to higher customer satisfaction and profitability.