AmbaFlex Scales Service Operations with Microsoft Dynamics 365 Field Service

AmbaFlex, a global leader in spiral conveyor systems, faced service inefficiencies. Zelite Solutions improved operations by implementing Microsoft Dynamics 365 Field Service, offering centralized work order management, automated scheduling, a mobile app for real-time access, and enhanced communication.

Industry

Time Required

Engagement Model

Solution

Current Phase

Technologies

Introduction

AmbaFlex, a leading global provider of customized material handling systems based on spiral conveying technology, prides itself on exceptional customer service and innovative solutions. However, their existing service management system lacked functionalities for efficient scheduling, real-time communication, and technician empowerment. This case study explores how Zelite Solutions implemented Microsoft Dynamics 365 Field Service (D365 FS) to transform AmbaFlex’s service operations, enabling them to deliver superior service experiences while optimizing technician productivity.

Challenges

- Manual Workflows: Scheduling, dispatching, and work order management relied on manual processes, leading to inefficiencies and potential errors.

- Limited Communication: Communication between service representatives, technicians, and customers lacked a central platform, hindering transparency and timely updates.

- Inefficient Data Management: Important service data like maintenance history and parts inventory were scattered across various sources, making it difficult to access and utilize for informed decision-making.

- Limited Technician Visibility: The lack of mobile access for technicians restricted real-time updates and efficient on-site service delivery.

AmbaFlex's Requirements

- Centralize Service Operations: Consolidate all service activities – scheduling, dispatching, work order management, and communication – into a unified platform.

- Optimize Scheduling and Dispatch: Implement an automated scheduling system that considered technician location, skillset, and job complexity for efficient resource allocation.

- Empower Technicians with Mobile Technology: Equip technicians with a mobile app for real-time access to work orders, customer information, parts inventory, and communication tools.

- Improve Data Visibility and Insights: Gain a centralized view of service data to identify trends, optimize service delivery, and make data-driven decisions.

Solution

Zelite Solutions implemented Microsoft Dynamics 365 Field Service (D365 FS) to address AmbaFlex’s challenges and create a comprehensive service management platform. Key functionalities of D365 FS included:

Centralized Work Order Management:

A single platform for creating, assigning, tracking, and managing work orders for various service requests (installation, maintenance, repair).

Automated Scheduling and Dispatch:

D365 FS utilized advanced algorithms to consider technician location, skillset (e.g., electrical expertise for specific SpiralVeyor models), and job complexity when assigning work orders. This ensured the right technician was dispatched for the job, minimizing travel time and improving first-time fix rates.

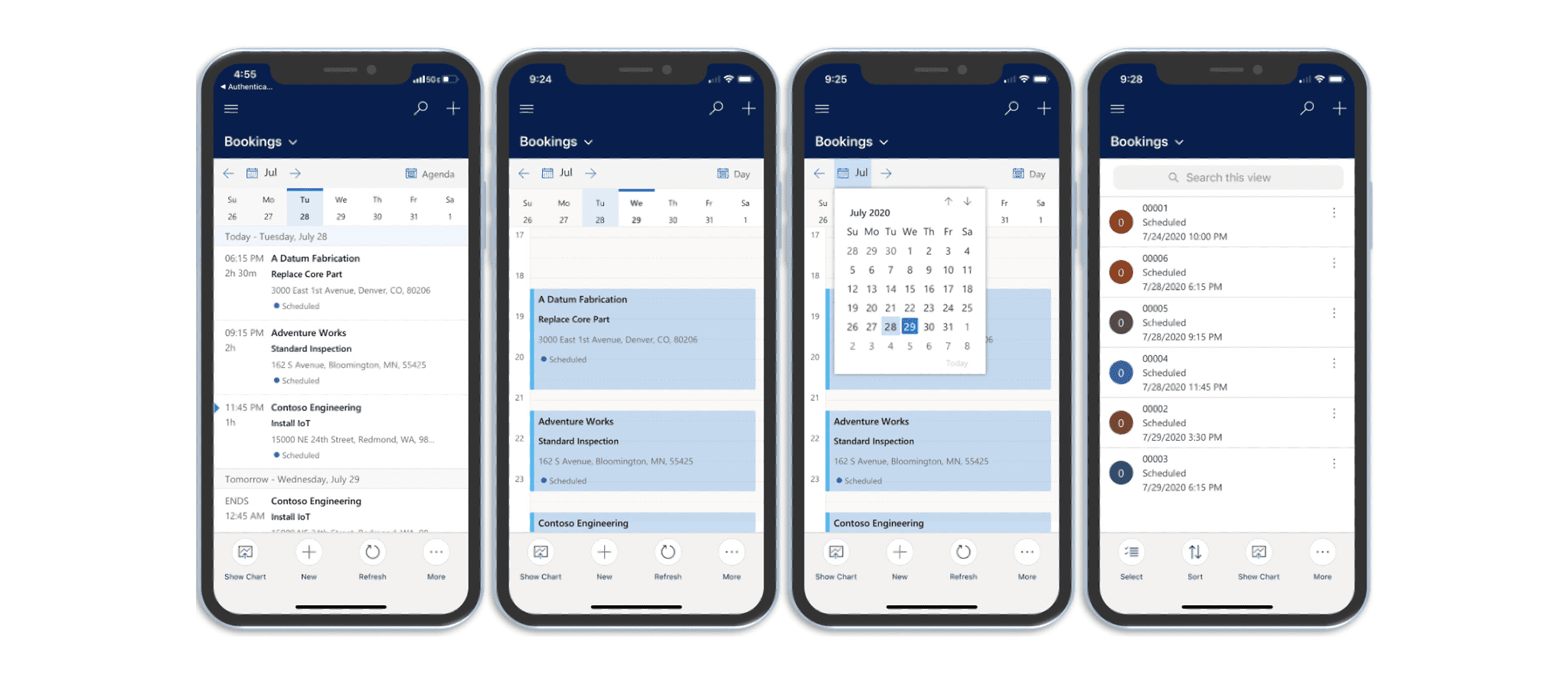

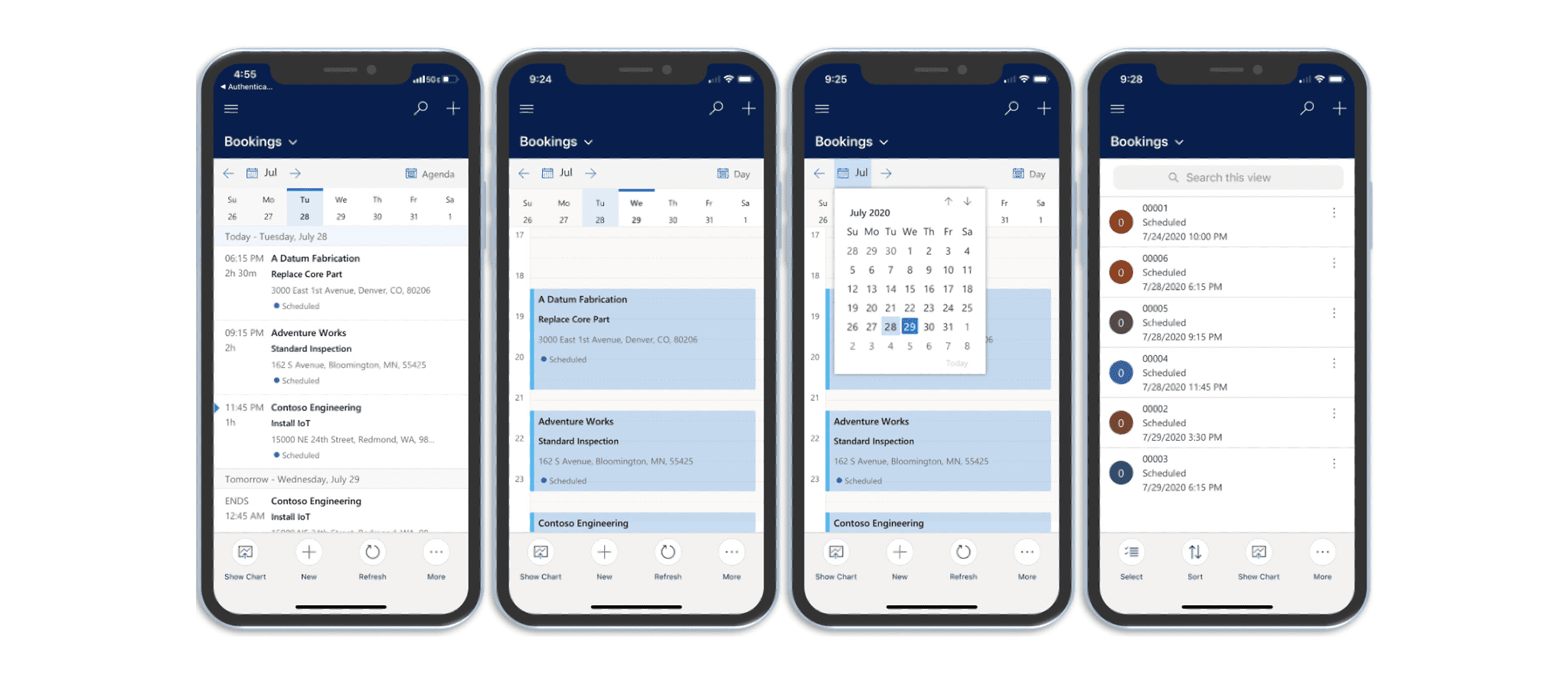

Mobile App for Technicians:

The D365 FS mobile app empowered technicians with real-time access to work orders, customer details, service history, and parts information. The app facilitated:

- Navigation to customer sites using GPS integration.

- Access to digital manuals and schematics for troubleshooting and repair.

- Real-time updates on work progress, parts used, and completion status.

- Photo capture capabilities to document service activities and completed work.

Improved Communication:

- D365 FS facilitated seamless communication between service representatives, technicians, and customers.

- Service representatives could communicate work order updates and receive real-time technician progress reports.

- Technicians could directly communicate with customers regarding service details, estimated completion times, and any part replacements needed.

- Customers received automatic notifications on technician arrival times, service updates, and completion status.

Inventory Management:

- D365 FS offered integrated inventory management capabilities.

- Service representatives could view real-time parts availability at regional warehouses or within service vehicles.

- The system could automatically generate purchase orders for parts needed during service calls, minimizing delays.

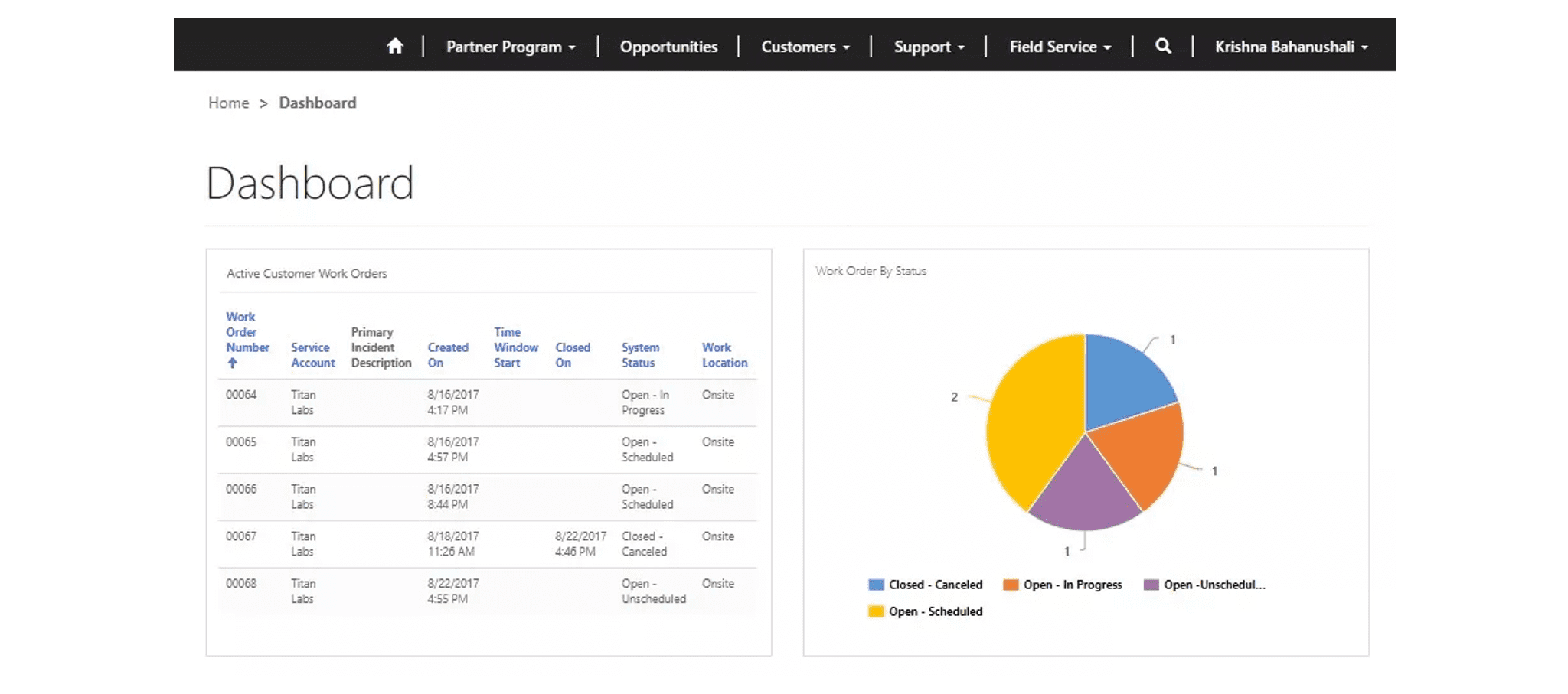

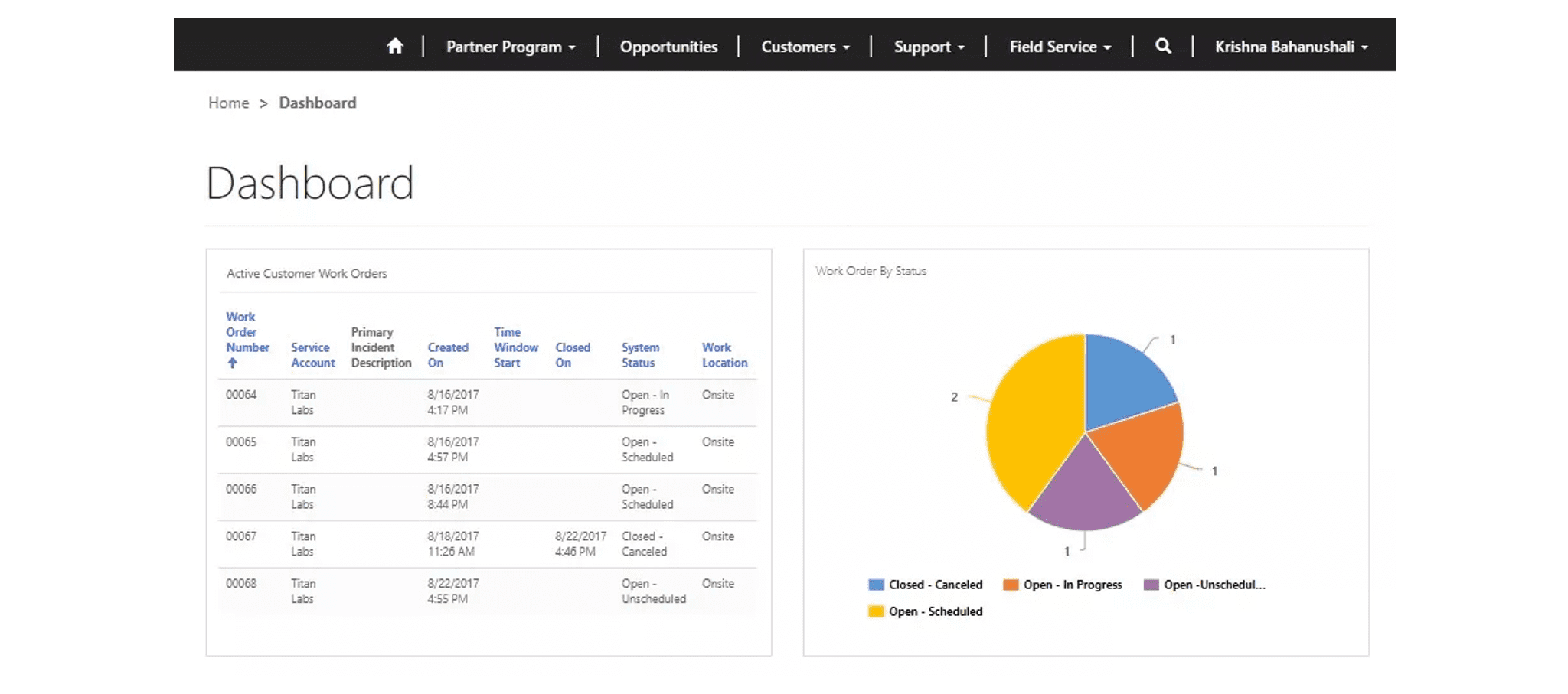

Service Reporting and Analytics:

- D365 FS provided comprehensive reporting and analytics functionalities.

- AmbaFlex gained insights into technician performance metrics (e.g., average resolution time, first-time fix rate), parts usage trends, and customer satisfaction feedback.

- This data empowered data-driven decision-making for optimizing service scheduling, technician training, parts inventory management, and proactive maintenance strategies.

Implementation Process

Zelite Solutions followed a structured approach to implement D365 FS for AmbaFlex:

- Data Migration and Integration: Existing service request data, technician information, and parts inventory data were migrated to D365 FS. The platform was then integrated with AmbaFlex’s CRM system and accounting software for a unified data flow.

- System Configuration and Customization:

- Custom fields were added to work orders to capture specific details relevant to SpiralVeyor systems (e.g., model type, serial number, maintenance history).

- The mobile app interface was customized to provide technicians with easy access to digital manuals and schematics for various SpiralVeyor models.

- Mobile App Deployment and Training: The D365 FS mobile app was deployed to technicians, followed by comprehensive training on its functionalities, work order management, real-time communication features, data capture protocols, and best practices for on-site service delivery.

Benefits

By implementing D365 FS, AmbaFlex achieved significant improvements in their service operations:

- Increased Efficiency:Streamlined workflows, automated scheduling, and mobile access for technicians significantly improved operational efficiency. Dispatch times were reduced, and technicians completed jobs faster, leading to increased service capacity.

- Enhanced Customer Experience:Improved communication, real-time updates, and first-time fix rates resulted in a significantly enhanced customer experience. Customers received timely updates on service progress and benefited from efficient on-site service delivery.

- Empowered Technicians: The mobile app empowered technicians with real-time access to information, parts availability, and communication tools. This improved their productivity, problem-solving capabilities, and overall job satisfaction.

- Data-Driven Decision Making: D365 FS reporting and analytics provided valuable insights into service operations. AmbaFlex could identify trends in maintenance requests, optimize parts inventory based on usage, and make data-driven decisions for continuous service improvement.

- Improved First-Time Fix Rate:Automated scheduling based on technician skillset and access to service history on past installations or repairs of similar SpiralVeyor models led to a 11%in the first-time fix rate, reducing repeat visits and improving customer satisfaction.

- Reduced Downtime for Customers:Improved maintenance efficiency and proactive service strategies based on data insights minimized equipment downtime for AmbaFlex’s customers, ensuring optimal production.

Conclusion

By implementing Microsoft Dynamics 365 Field Service, AmbaFlex successfully transformed their service operations. D365 FS provided a comprehensive solution that enabled them to:

- Centralize service operations for efficient work order management and improved visibility.

- Optimize scheduling and dispatch processes to ensure the right technician is assigned to the right job at the right time.

- Empower technicians with mobile technology for efficient on-site service delivery and real-time communication.

- Enhance customer experience through improved communication, transparency, and faster service resolution.

- Gain valuable data insights for data-driven decision making and continuous service improvement.

This transformation empowered AmbaFlex to maintain its leading position in the material handling industry. With D365 FS, AmbaFlex can deliver superior service experiences to its global customers, ensure efficient equipment operation, and achieve long-term success.